Foundry Division

Yesco Flow Control Engineers

Company Owned Land Area : 120000 Sq.Ft Building Covered Area : 25000 Sq.Ft

Pattern Shop Facility

• We have complete facility for Teakwood and Aluminium pattern manufacturing, mounting and repairing. • We have customer wise pattern storage. • We have got CAD/CAM Facility for method drawing.

Moulding Facility

The moulding department is supported by 5 ton overhead hoists to handle the closing, pouring and shifting the moulds.

• We carry out Co2 Process with hand moulding. • CO2 Process cores, shell cores, no bake cores. • We have got 250kg & 150 kg sand mixture.

Melting Facility

• We are having a two crucible Induction furnace. • We are having two lip pouring and one Bottom pouring ladle. • Ladle preheating Arrangements. • Pyrometer For Molten metal Temperature measurements.

Heat Treatment Facility

• We have a 3000 Kg Electric Induction Furnace with digital thermocouple. • Full Equipped 60000 Litres capacity water Quench tank. • 3 ton overhead hoists to handle the castings loading and unloading. • Calibrated in presence of TUV Nord and IBR.

Fettling Facility

• We have 2 nos Swing frame Grinding Machines. • 12 nos rotto fettle grinding machines. • 500 Kg hook Type shotbalst machine. • Welding Machine 600amps rectifier with air arc Gouging. • Acid pickling and passivation facilities.

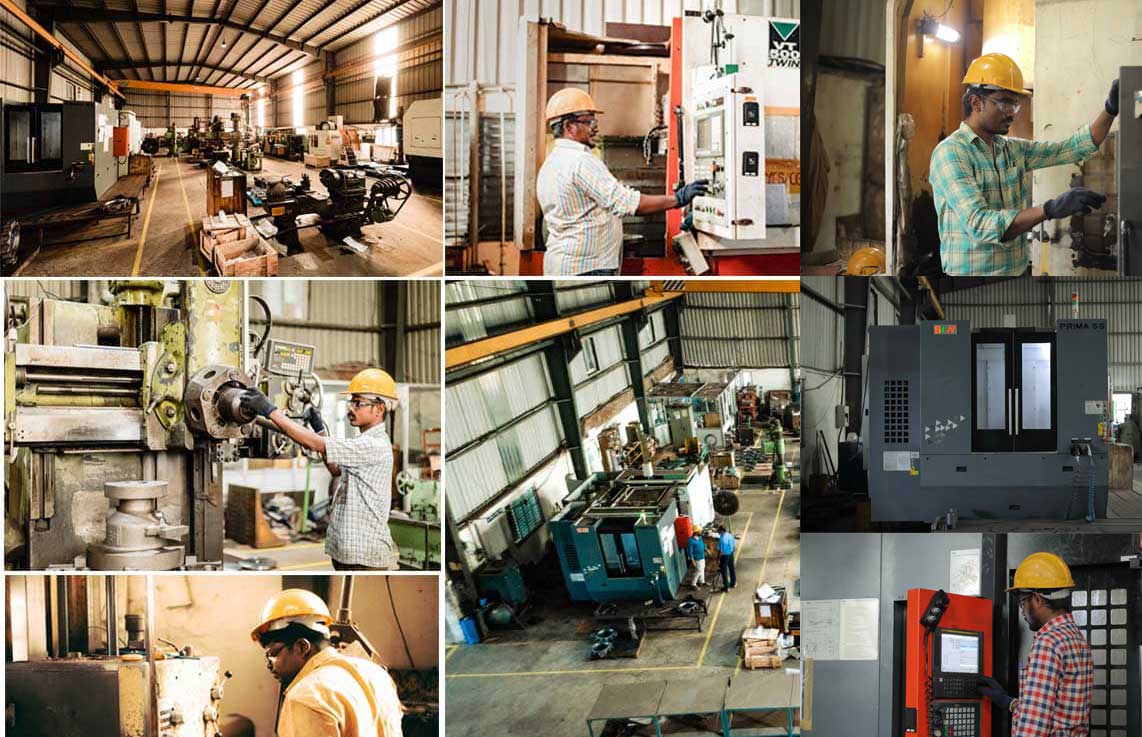

Machine Shop

• CNC Turning centre • VTL • VMC • HMC • Conventional machines like VTL, HBM, RDL and LATHE